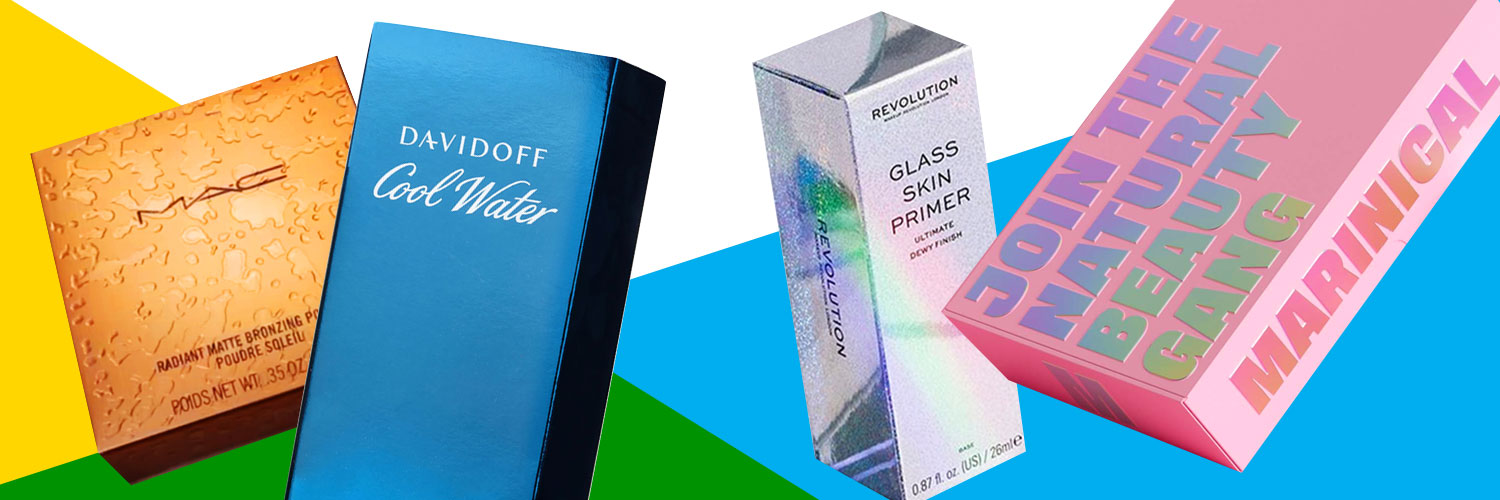

In both literal and figurative senses, laminates add a new layer to any packaging design project. When it comes to creating reflective packaging that glints like a diamond in the sun, you can count on holographic and metallized polyester. Metallic laminates allow products to shine in fun, luxurious ways, but each type comes with its own distinct characteristics. Because of their visual impact, they can be an immense help to brands looking to make their products stand out on crowded shelves. Below, we’ll discuss each laminate, and look at a few product packaging examples that use the laminate effectively.

THE MESMERIZING POWER OF HOLOGRAPHIC LAMINATES

Holographic laminates are a fast way to a buyer’s heart. There’s nothing quite like the gorgeous sheen of a holographic film, especially on fully stocked retail shelves, such as the wide selection of boxes in the toothpaste aisle. The retail packaging box for Crest’s 3D White Arctic Fresh toothpaste really stands out because of the holographic effects that cover the box, perfectly reflecting the arctic fresh feel of the toothpaste.

Holographic laminates are especially popular in the cosmetics industry because of their shiny, clean look. Vegan skincare line Marinical opted to cover its packaging boxes in a rainbow holographic film with embossed white text to great effect. Its modern, clean look balances inspiration from the early 2000s with futuristic materials to appeal to the brand’s audience of “skin-care savvy Gen-xers.”

Urban Decay did the same for its After Dark palette, covering the packaging box with a luminescent rainbow holographic laminate that moves and shines at every angle. The text “After Dark” appears to be reflected in the rainbow background, further accentuating this packaging’s depth and beauty to a mesmerizing effect.

The fun doesn’t stop at rainbow. One of the best things about holographic laminates is the number of potential patterns, colors, and effects to choose from. In addition to the rainbow labels in Revolution’s Glass Skin Collection, the brand also uses a cracked ice pattern on its Liquid Skin box and a glittering sparkle pattern for its Skin Primer. The different patterns give each product its own personal shine, and the holographic effects tie the entire collection together beautifully.

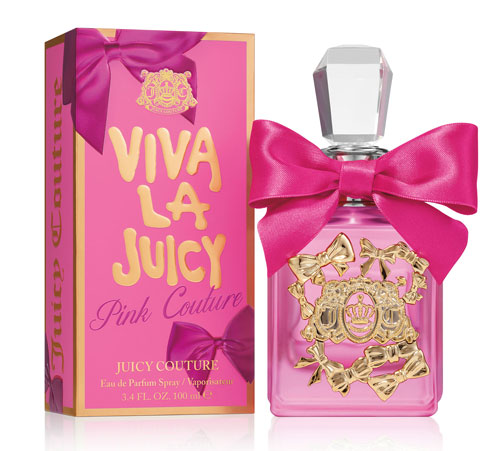

Fresnel lens holographic laminates produce different kinds of dynamic 3D effects. For instance, the magenta pink squares on Juicy Couture’s Viva la Juicy Soirée Perfume box give depth to the packaging, beckoning to anyone scanning retail shelves.

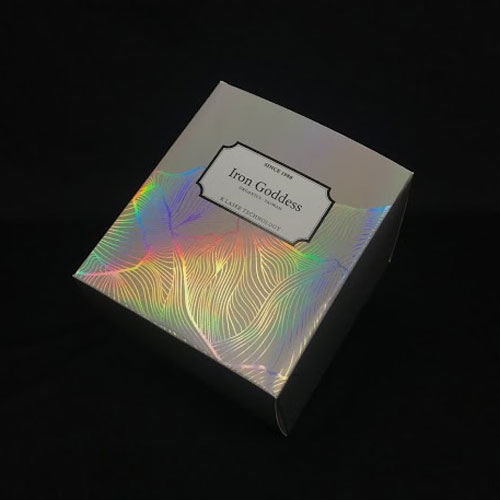

For a more subtle approach, consider the use of holographic lamination in this packaging design concept for a project named Scents of Ilha Formosa. Designed for a line of Taiwanese tea scented candles, the packaging seeks to combine tradition and the modern. According to Packaging of the World: “Traditionally, tea culture represents the image of mild, gentle, elegance and graceful. Its aroma depends on several factors such as water temperature and brewing time, like how holographic materials reflect different viewing angles and lighting environments.” To successfully convey this idea, each pastel box is covered in delicate holographic lines, depicting beautifully shimmering mountains.

ROCK OUT TO SOME HEAVY METAL-LIZED POLYESTER LAMINATES

There are a few types of metallized polyester laminates, but they’re all cut from the same cloth (well, from the same sheet of polyethylene terephthalate, or PET for short). Metallized Polyester laminates, also known as Metpol, Met-Poly, MET-PET, and probably a few hundred other names, are made by metallizing a thin PET film and laminating that onto the base layer of paper or board. The result is a durable, PET film that has a high reflectivity and sheen similar to actual foil-laminated boards. Plus, the laminate is available in a wide range of finishes and virtually any color.

Much like similarly reflective holographic laminates, MetPol has become a major player in the world of fashion and cosmetics packaging. It’s used on the packaging for Cool Water perfume, a successful scent from Davidoff, to create a simple yet effective design. The reflective blue hues created by the shiny, almost luminous blue polyester are all the box needs to stand out.

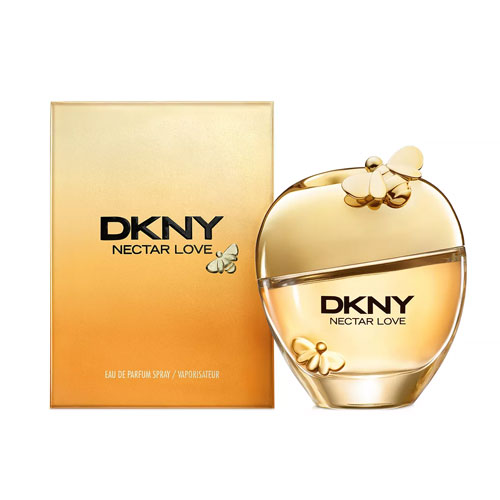

Kate Spade’s Live Colorfully Luxe perfume exudes glamour through the use of a bright gold MetPol box. The gleaming box plays well with the perfume container’s gold features and tempts buyers with the promise of a luxury experience. The same can be said for the use of MetPol on the packaging box for DKNY’s Nectar Love perfume, which fades from a light, white-gold to a rich honey gold sheen. This effect perfectly complements the delicate gold bee on the outside of the box and on the perfume bottle inside.

The packaging design for all three of these perfume examples, beyond the laminate, is relatively sparse—highlighting the importance and power of this tactful material choice in modern packaging design.

MAC added a special twist to its use of MetPol for its Summer 2020 Bronzer collection. After laminating the box with a reflective bronze, the cosmetics brand added a polymer splatter finish, adding a gorgeous texture to the box that’s just asking you to pick it up.

Such applications aren’t limited to beauty products. Take a look at Neat Confections’ packaging, which was beautiful enough for Dieline to sing its praises. The high-end confections shop focuses primarily on unadorned, flavor-forward cookies. They even note that there are “no added decorations, in order to place the savory experience on center stage.”

To complement their gorgeously simple handmade cakes and cookies, Neat Confections opted for a more alluring MetPol reflective packaging. Each sleeve pulls out like a cabinet drawer from an entirely silver box, with a smaller paper sleeve featuring pastel splashes and clean text explaining the brand and flavor. With the silver MetPet laminate, even cookies can be transformed into a luxurious experience. In fact, the brand even encourages its customers to pair its confections with Rosé!

Metallized Polyester laminates provide a flexible, gorgeous, and durable option for packaging designers looking to add a dose of luxury and fun to their packaging. Now, we could also talk about how Metallized Polyester films are critical in designing modern spacesuits for astronauts, but that feels like a blog post for another time…

TAKING A SHINE TO HOLOGRAPHIC AND POLYESTER LAMINATES

FREQUENTLY ASKED QUESTIONS

In the packaging world, lamination is the process of bonding a coating or a film to paper or paperboard (also known as “the substrate”). The way that this is done largely depends on the material being used, and layflat management procedures are key in ensuring the lamination doesn’t curl, ripple, or wrinkle.

A better question is: What aren’t the benefits of packaging lamination? Laminates can make packaging stronger and more tear-resistant, protect a package from light, moisture, and heat, and prolong the freshness of the product inside. Because there are so many different customization options, lamination is also a great way to help a product stand out.

Metallized polyester laminates are made through a special process of heating a small amount of metal, often aluminum, and bonding it to a cold, plastic sheet (made of PET). This creates a permanent metallization effect on the PET, which can then be laminated to a base material.

Yes! Given modern production capabilities, these types of laminates are available in a wide range of finishes, colors, and patterns, allowing each type to be customized however the buyer sees fit. There are options for patterns, like diamond plaid or cracked ice; finishes, like matte or gloss; or colors. Visit our product page to learn more about each type.