For packaging designers, every new project presents new challenges. These unique challenges drive innovation in design, and materials play a crucial part. Even the most familiar materials have inherent properties that are often under-recognized or under-utilized, and careful consideration and thoughtful selection can give rise to amazing packaging design innovations and trends. It’s not surprising that laminates and coatings of all sorts—those that are well-known to designers as well as those that may be less familiar—are contributing to innovative packaging design today.

LAMINATION & MODERN PRODUCT PACKAGING DESIGN

In this article, we’ll take a look at a few categories of lamination that offer new possibilities for many types of product packaging. All kinds of coatings and films are available with various nuances, and they produce a wide range of effects. For the most part, laminations offer a variety of cosmetic benefits, but these same laminations and coatings can also enhance structural integrity or offer unique functionalities like safe contact with food or heat resistance. Let’s dive in.

1. HOLOGRAPHIC LAMINATES

Holographic laminates are a stunning way to enhance commonplace, plain-Jane packaging, and they are tremendously functional to boot. Holographic laminates are often made using a PET film, but a holographic look can also be achieved with a hot stamping or cold foil. For a prime example of the aesthetic power of holographic laminates, look no further than Fenty Beauty’s first-ever holiday capsule, the 2017 “Galaxy” Holiday Collection. The boxes for all of the products in the collection are covered in a sheer rainbow holographic foil as shiny and alluring as the makeup inside. As if that’s not impressive enough, bold, glittery text and patterns splatter across the smooth holographic background, showcasing Rihanna’s fierce cosmetics brand.

Holographic effects don’t have to cover the entire box, either. For more subtle enhancements, dental floss brand Cocofloss uses rainbow foil to spell out the text on its bright, colorful boxes that are sure to stand out aside typically bland dental packaging. The silver Fresnel lens on the front of box for Dunhill’s Century Blue perfume has a special draw with a high-quality 3D effect, upping the ante for the luxury fragrance brand.

In regard to utility, there are a number of functional uses for holographic laminates as well. Transparent holographic films, for example, can add an extra layer of tear resistance to packaging, ensuring that a product is tamper-free. Unique holographic patterns are more difficult to counterfeit, as can customized holographic QR codes.

2. PATTERNED HOLOGRAPHIC LAMINATES

We’re not done with holographic packaging just yet. One of the most exciting things about holographic laminates is their customization and versatility. In fact, there’s a whole swatch library of holographic patterns and colors you may have never even heard of that can add even more pizzaz to shiny, alluring packaging.

Before looking at some examples, here’s a non-exhaustive list of unique holographic laminate patterns:

- Pillars of light

- Sparkle dots

- Plaid

- Lava

- Cracked Ice

- Confetti

- Starbursts

- Rain drops

- Checkers

- Diamonds

- Pillars of light

- Sparkle dots

- Plaid

- Lava

- Cracked Ice

- Confetti

- Starbursts

- Rain drops

- Checkers

- Diamonds

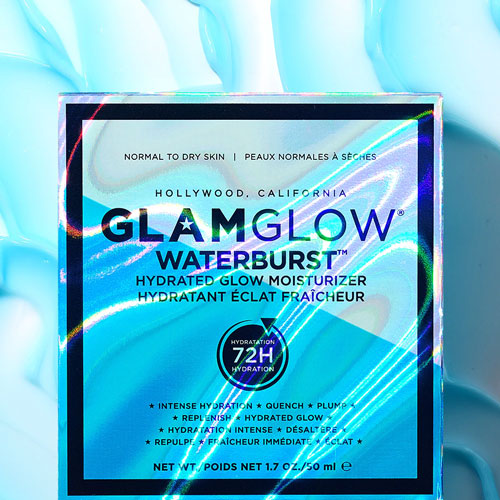

Patterns can also be customized in all sorts of ways. Consider playing with a mix of holographic pattern and color: GlamGlow’s WATERBURST moisturizer box incorporates a cool blue tint in its lava holographic laminate to great effect. Hungry Jacks’ 2016 French fry boxes are covered in a dazzling, custom-branded pattern that was designed to scare away seagulls.

For design inspiration, notice the diamond plaid holographic pattern on Sensodyne’s Tartar Control boxes, the elegant sparkly dots pattern for Paris Hilton’s Rose Rush perfume, or the liquid lava pattern of the box for Urban Decay’s Shapeshifter and Afterglow palettes.

3. ALUMINUM FOIL LAMINATES

The roll of aluminum foil in your kitchen pantry can do a lot. It’s great for grilling, for storing your barbecue’s leftovers, and even for scrubbing the grill grate clean after cooking. Not only is aluminum foil food-safe, it’s also plastic-free, lightweight, and markedly recyclable (it’s even dishwasher safe!). In fact, according to the Aluminum Association, nearly 75% of all aluminum produced is still in use today.

It’s no surprise then that aluminum foil laminates are widely used in all kinds of food, cosmetics, and chemical packaging. Foil laminates are FDA compliant for direct food contact and effective heat and moisture barriers. Plus, they have the best high dead fold properties in the business, meaning foil-laminated packaging won’t spontaneously unfold or lose its form.

Aluminum foil was popularized in America by Reynolds Metals—yep, that’s the same company of the Reynolds Wrap fame, and yes, of course they add aluminum foil laminates to all of their packaging boxes. Many packaging companies have caught on to the decorative power of foil—using hot foil stamping or embossing techniques to add a special shine to otherwise plain packaging. One great example of this comes from the Cannabis brand Bloom Farms. Each paperboard box for its individual cannabis hand rolls is luxurious, enhanced with gold, silver, or black matte foils in the shape of the product’s iconic five-leafed plant for Bloom Farms’ ideal customer—the cannabis connoisseur.

4. POLYESTER LAMINATES & METALLIZED MYLAR

Polyester laminates, often referred to as PET laminates, are PET film adhered to a fibrous substrate to create a laminated material used for enhanced packaging. Polyester is a durable material, so it’s good for packaging that needs to stand out while maintaining a relatively rigid structure.

One standout example of a PET-laminated packaging design is Urban Decay’s Go Naked perfume oil. The packaging has a gorgeous metallic sheen (this PET laminate is a metallized polyester laminate), and has a distinct tactile feel. Effects like these are important for cosmetics customers who look for the promise of beauty right on the packaging, but this packaging isn’t just great looking, it’s also sturdy enough to confidently carry the glass perfume bottle.

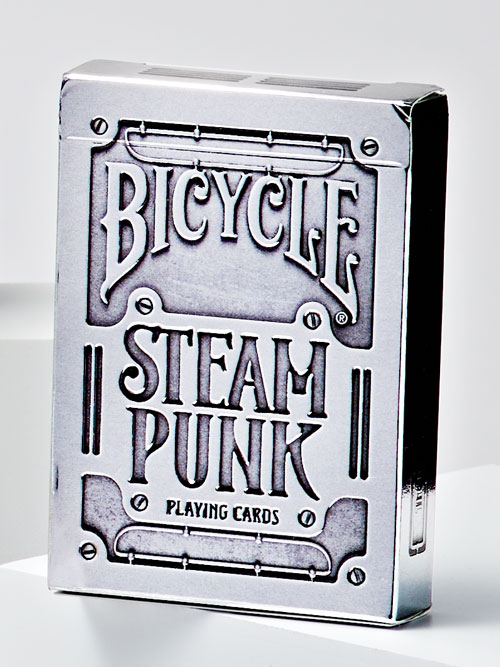

Another great example is renowned card brand Bicycle’s Silver Steampunk Playing Cards. The box that holds the cards evokes metalwork and machinery often associated with the Steampunk genre, and is finished with polyester lamination, showcasing an effective metallic look without compromising the box’s integrity (and without the weight and expense of an actual-metal card deck). Metallized mylar is another term for this style of lamination, as mylar is a type of polyester film with a high tensile strength and strong insulation qualities.

5. TRANSFER METALLIZED LAMINATES

Transfer metallized laminates are yet another way to get a bright, almost reflective sheen on your final product packaging. With these laminates, a thin layer of metallic foil is bonded to the base layer with a sustainable, water-based adhesive, and the polyester film can be removed for responsible recycling, leaving behind a fully recyclable laminate. Fun fact: the foil itself is less than 0.1 micron thick. For reference, a single human hair is about 70 microns thick (in diameter). So, when we say thin layer, we really mean thin layer. Transfer metallized presents an attractive, sustainable, and tearable option for packaging that needs a bright, metallic finish. Plus, it’s typically available in multiple styles, like silver, rainbow, or even various custom holographic patterns.

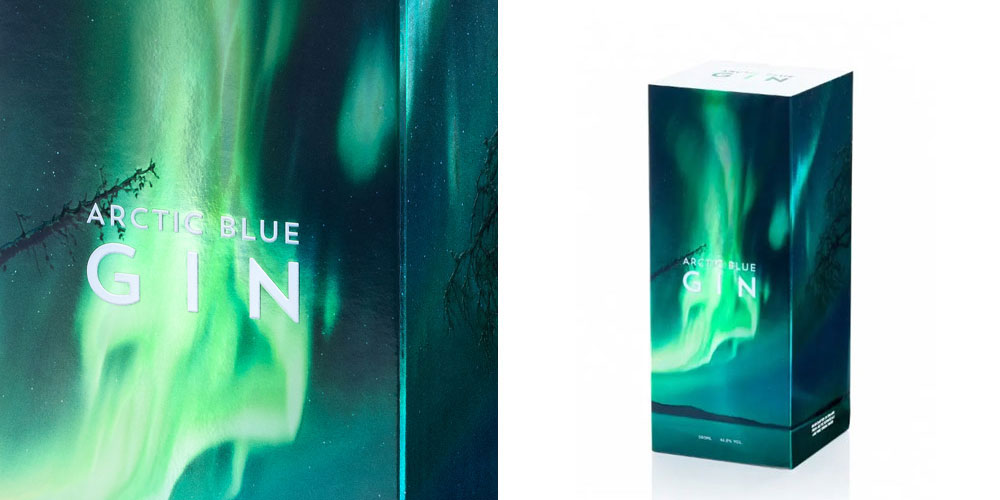

One fantastic example of this laminate in action is Arctic Blue Gin. This high-class liquor packaging is absolutely stunning and presents a sterling invitation for would-be gin drinkers. The branding leans on the natural beauty of the northern lights and prints over a high-res picture with transfer metallized laminates to mimic the natural event’s typical, cosmic glow. The final result is beautifully designed, with visuals that are made possible by the choice of materials—in this case, transfer metallized laminates on top of a sustainable MetsäBoard paperboard offering.

SHINE BRIGHT LIKE A DIAMOND (OR LIKE A LAMINATED SHEET)

Seasoned designers know that there are plenty of ways packaging can stand out, and laminates can be an amazing addition to the designer’s toolbox. They offer a wide range of options for creating entirely new effects and styles. Furthermore, most laminates not only preserve the packaging’s durability and function, they also enhance it. With lamination, bland packaging options are transformed into potential-filled canvases, ready for a holographic cracked ice pattern or a reflective, heat proof silver foil. The possibilities are nearly endless. To learn more about packaging design, and to look at some exceptional examples (including some laminated ones), our more detailed report on upcoming packaging trends can be found here.

FREQUENTLY ASKED QUESTIONS

Holographic laminates are typically made using a PET film, but the holographic effect can also be achieved via a hot stamping or cold foil. Patterns and colors are highly customizable, and holographic laminates can add an extra layer of protection since holographic designs are generally more difficult to counterfeit.

Aluminum foil laminates are FDA compliant for most direct food contact, provide effective heat and moisture barriers, and have high dead fold properties, ensuring the form of foil-laminated packaging won’t spontaneously rebound. It’s also a lighter weight than metallized polyester (MetPol) and 100% recyclable.

Polyester laminates (known as PET laminates) are PET film adhered to a fibrous substrate to create a laminated material used for enhanced packaging. Polyester is a durable material, so is great for packaging that needs to both stand out and maintain a relatively rigid structure.

Metallized mylar is another type of polyester film metallized with aluminum, with a high tensile strength and heat resistance.

Less than 0.1 micron thick, transfer metallized laminates are a thin layer of metallic foil that has been bonded to the base layer of a package with a sustainable, water-based adhesive. After bonding, the polyester film substrate for the metal is then removed and responsibly recycled.